Scale your kitchen operations through clever automation.

Just-right temperature, all day.

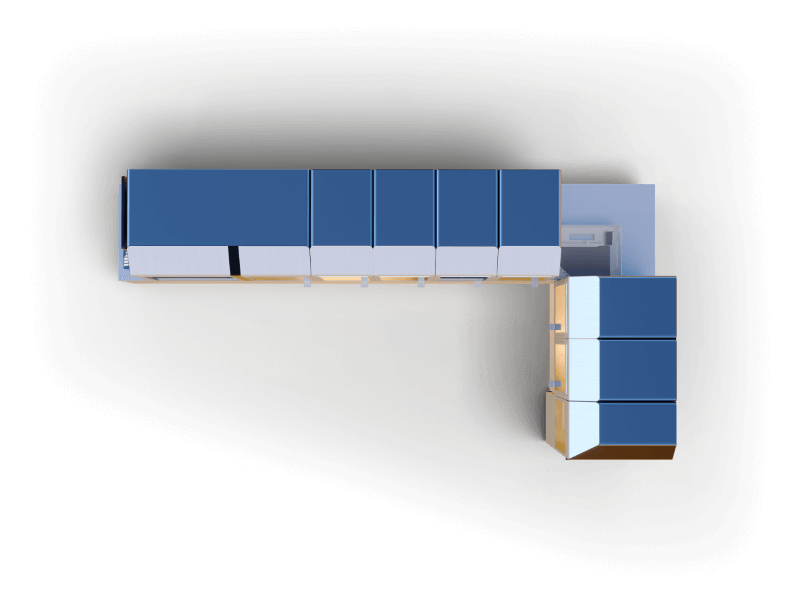

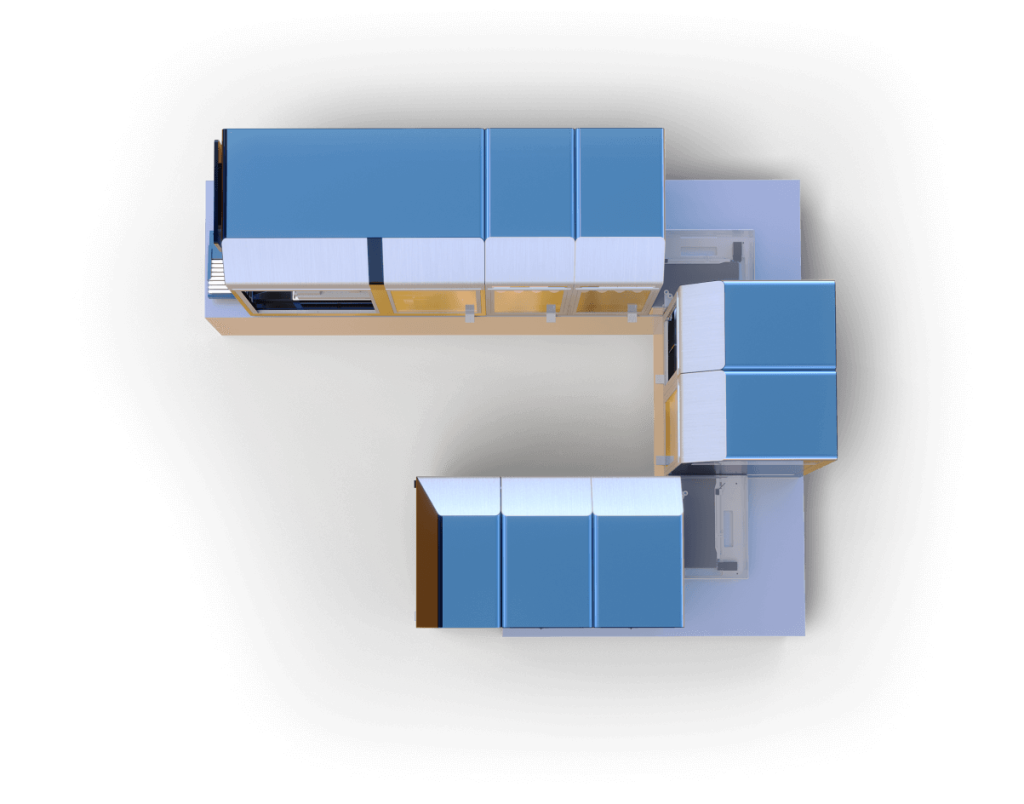

The Super Tomato One is modular, accurate and always hygienic. Time to make room for a new kitchen hero that takes up less space.

You do the menu, we’ll do the machines. The ability to process and dispense more ingredients within a smaller footprint means your expanding menu doesn’t rely on more kitchen space.

We’re never not R&D-ing. So we’re always open to collaborating with partners to create even more clever automation solutions. In fact, we’d love to!

We harness the power of robotics to improve the human experience. If your love for technology is a match for your drive to make lives better, get in touch.

We want you on our team.

EXCELLENTTrustindex verifies that the original source of the review is Google. Really professional quality for my aluminium machining prototype, with a nice anodized finish and detailed custom laser engraving. Very smooth order overall, with minor change improvements to the prototype suggested by Monster Builder during the process. Highly recommended, thank you Niles and team!Posted onTrustindex verifies that the original source of the review is Google. Super fast, great communication, great pricing, and excellent qualityPosted onTrustindex verifies that the original source of the review is Google. Great experience dealing with Monster Builder. Out of the many fabrication providers that I have reached out to, Monster Builder is the most responsive one. And when I brought my item down for cutting, Yeeling and Dan attended to my request despite having no appointment arranged. Both of them are very friendly and helpful. Really appreciated that. While visiting, I come to know more of what they do (I assumed I understood correctly) and it is really inspiring. And also they have a nice, air conditioned office/workshop. Will definitely go back to them.Posted onTrustindex verifies that the original source of the review is Google. Worked two times with them. So far so good.Posted onTrustindex verifies that the original source of the review is Google. Ordered a bespoke BBQ grill. Staff have been very patient - answering questions, providing proper drawings prior to production. Timeline for production was accurate and timely. Highly recommend if you need anything custom made.Posted onTrustindex verifies that the original source of the review is Google. Prompt and professional service, highly recommended, just ensure sufficient information is provided for the fabrication, and ensure that all the requirements are clearly stated.Posted onTrustindex verifies that the original source of the review is Google. Good servicesPosted onTrustindex verifies that the original source of the review is Google. So accommodating and helpful!!Posted onTrustindex verifies that the original source of the review is Google. Niles and team were responsive to our requests and delivery of item was prompt. Would definitely recommend a face to face meeting to discuss requirements as we were able to draw from their expertise to best adjust our initial designs.Posted onTrustindex verifies that the original source of the review is Google. 1st time liaise with them. Prompt response with excellent service. Thank you, Super Tomato.

Dispensing module

Ingredient-savvy.

Temperature-controlled.

End-line module

Load. Lid. Label.

Repeat.

Integrated software

Operations and analytics, in one.

KDS (Kitchen Display Screen)

RMS (Restaurant Management System)

QDS (Queue Display System)